Products >> Steel Pipes/Tubes/Chromed Bars >> Hydraulic cylinder tubing

DIN 2391 Hydraulic Pipe Supplier

- Product No.:20241120142423

DIN 2391 Cold-Drawn Hydraulic Pipe Supplier

DIN 2391 is a well-known German standard that specifies the technical delivery conditions for seamless precision steel tubes, primarily used in hydraulic systems. These tubes are manufactured using cold drawing, which enhances their mechanical properties and ensures precise dimensions. The DIN 2391 standard covers several steel grades and is recognized for producing high-quality pipes with excellent surface finish, dimensional accuracy, and mechanical strength.DIN 2391 seamless tubes are ideal for high-pressure applications, particularly in hydraulic and pneumatic systems, as well as automotive, engineering, and machinery industries. They offer superior corrosion resistance, making them reliable in harsh environments.

Key Features of DIN 2391 Tubes:

- Precision: These tubes are crafted with extreme accuracy in diameter and thickness.

- Strength: DIN 2391 tubes are designed to handle high pressures and mechanical stresses.

- Cold-Drawn Process: Enhances surface quality, strength, and reduces wear and tear.

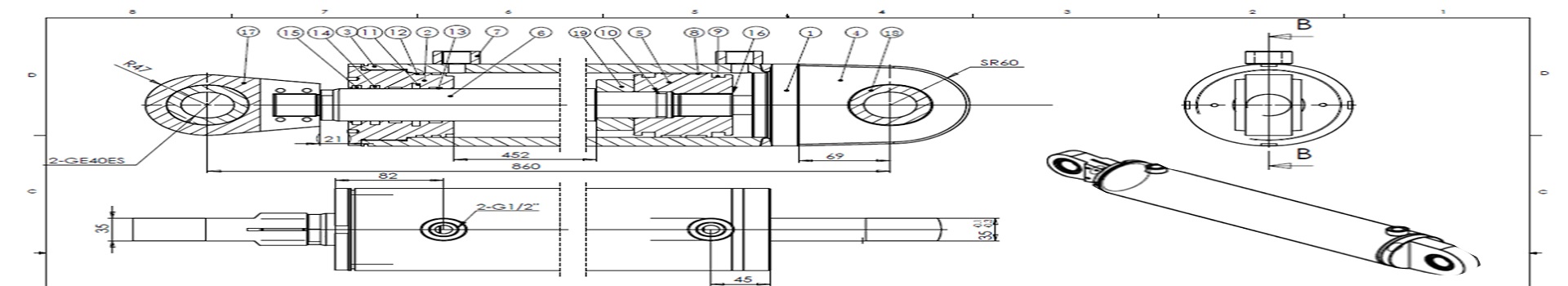

These tubes are commonly used in producing hydraulic cylinders, fuel injection systems, and other components where precision and durability are critical.

DIN 2391 Cold-Drawn Tube

includes several steel grades, each offering specific properties suited for different applications. These steel grades are categorized mainly based on their chemical composition and mechanical properties, making them ideal for hydraulic systems, automotive, and industrial applications. Below are the most common steel grades covered under the DIN 2391 standard:

1. ST37.4 (Equivalent to EN 10305-1 E235)

- Carbon content: Low (about 0.17%)

- Characteristics: This grade is known for its good formability and weldability. It's used in less demanding hydraulic and pneumatic systems.

- Application: Ideal for low-pressure applications in mechanical engineering and automotive components.

2. ST44.4 (Equivalent to EN 10305-1 E275)

- Carbon content: Moderate (about 0.21%)

- Characteristics: Offers higher strength than ST37.4 with good elongation and toughness.

- Application: Common in medium-pressure hydraulic systems and mechanical structures.

3. ST52.4 (Equivalent to EN 10305-1 E355)

- Carbon content: Higher (about 0.22%)

- Characteristics: Known for its high tensile strength and toughness, making it suitable for high-pressure hydraulic applications.

- Application: Widely used in high-stress, high-pressure hydraulic systems, automotive engineering, and heavy machinery.

4. C45E

- Carbon content: Moderate (about 0.45%)

- Characteristics: A medium carbon steel with higher tensile strength and hardness, commonly used when wear resistance is required.

- Application: Hydraulic and mechanical components that demand higher strength and moderate wear resistance.

5. E355N

- Characteristics: This steel grade offers high strength and is usually normalized to ensure uniform mechanical properties. It's suited for demanding applications.

- Application: Hydraulic systems requiring high reliability under pressure, heavy machinery, and structural components.

6. 20MnV6

- Characteristics: Alloyed with manganese and vanadium, this steel grade provides excellent machinability and wear resistance while maintaining strength.

- Application: Ideal for hydraulic cylinders and applications involving heavy mechanical loads.

These various steel grades under DIN 2391 ensure that seamless precision steel tubes meet the specific requirements of different industries, particularly in high-pressure and high-stress environments. Choosing the right grade depends on the application’s pressure, mechanical stress, and environmental conditions.

ABOUT XUDSTEEL

As a leading manufacturer of hydraulic cold-drawn tubes, XUDSTEEL provides a wide range of seamless tubes, hydraulic cylinder tubes, and precision cold-drawn tubes to customers worldwide. Our precision seamless steel tubes have earned a strong reputation for their consistent quality and competitive pricing, making them a trusted choice in the industry.

Our tubes and pipes are extensively used in hydraulic cylinder systems due to their excellent mechanical properties, ensuring long-lasting performance even in demanding applications. At XUDSTEEL, we are equipped with advanced production facilities that enable us to manufacture cylinder tubes, honed tubes, cold-drawn tubes, and cylinder barrels with high precision and tight tolerances.

We are committed to delivering reliable, high-quality products that meet the specific needs of our customers. We welcome partners and clients from around the globe to visit us and explore opportunities for long-term cooperation.

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry