Products >> Steel Pipes/Tubes/Chromed Bars >> Seamless steel pipe

ASTM A53 Steel Pipe

ASTM A53 Steel Pipe

ASTM A53, a standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded, and seamless, is widely recognized in the piping industry. The American Society for Testing and Materials (ASTM) developed this specification, which outlines the requirements for materials, manufacture, and testing of these pipes. This standard is critical for ensuring quality and consistency in the production of steel pipes used in various applications, including transportation of steam, water, and gas, as well as structural applications.

1.1 Specifications and Types of ASTM A53 Pipe

ASTM A53 pipes are available in three types: Type S (seamless), Type E (electric-resistance welded), and Type F (furnace-welded).

Additionally, they come in two grades, A and B, with Grade B having higher yield and tensile strength. These pipes are produced in either black or hot-dipped galvanized finishes.

1.2 Types of ASTM A53 Pipe

Type S (Seamless): Manufactured without a weld seam, these pipes are produced by extruding the metal to the desired length. They are typically more robust and can handle higher pressure and temperature variations.

Type E (Electric-Resistance Welded): These pipes are made by forming a strip of steel into a cylindrical shape and welding the seam using electrical resistance. This method is efficient and cost-effective, suitable for moderate-pressure applications.

Type F (Furnace-Welded): These pipes are created by heating the edges of the steel strip until they are malleable and then forcing them together to form a welded joint. This method is less common and primarily used for lower-pressure applications.

1.3 Grades of ASTM A53 Pipe

Grade A: This grade offers lower mechanical strength and is suitable for light-duty applications where high-pressure resistance is not critical.

Grade B: Offering higher mechanical properties, Grade B is commonly used in industrial and mechanical applications requiring higher strength and durability.

1.4 Finishes and Coatings

Black Finish: These pipes are untreated, retaining their natural steel color and properties. They are often used in non-corrosive environments or where the external appearance is not a concern.

Galvanized Finish: These pipes are coated with a layer of zinc to enhance their corrosion resistance, making them suitable for outdoor and harsh environmental conditions.

Applications and Benefits of ASTM A53 Pipe

ASTM A53 pipes are versatile and used across a wide range of industries due to their robustness, durability, and adaptability to various environments. Their applications span from plumbing to industrial, and structural projects.

2.1 Industrial Applications

In industrial settings, ASTM A53 pipes are used for conveying water, steam, and gas. The seamless and electric-resistance welded types are preferred for high-pressure applications such as oil and gas transportation, power generation, and chemical processing. The robustness of Grade B pipes makes them ideal for these demanding environments.

2.2 Structural Applications

ASTM A53 pipes are also integral to structural applications, where they serve as columns, beams, and supports. Their high strength-to-weight ratio and availability in large diameters make them suitable for construction frameworks, bridges, and other structural components. The galvanized finish provides added protection against corrosion, extending the lifespan of these structures.

2.3 Plumbing and Water Systems

In residential and commercial plumbing, ASTM A53 pipes are used for water supply and distribution systems. The corrosion-resistant properties of galvanized pipes make them suitable for potable water systems, ensuring long-term reliability and safety. Additionally, they are used in sprinkler systems and other fire protection installations due to their durability and compliance with safety standards.

2.4 Benefits of Using ASTM A53 Pipes

Durability and Strength: The high-quality steel used in ASTM A53 pipes ensures excellent mechanical properties, including tensile strength and durability, making them reliable for high-stress applications.

Versatility: Available in various types, grades, and finishes, these pipes can be customized to meet specific requirements across different industries.

Corrosion Resistance: The galvanized coating provides enhanced protection against corrosion, which is crucial for outdoor and industrial applications.

Compliance with Standards: Adherence to ASTM standards ensures that the pipes meet stringent quality and safety criteria, providing peace of mind to engineers and contractors.

ASTM A53 pipes are a cornerstone in the piping industry, offering a blend of strength, versatility, and reliability. Their wide range of types, grades, and finishes makes them suitable for numerous applications, from industrial to structural and plumbing. Understanding the specifications and benefits of ASTM A53 pipes helps in selecting the right type of pipe for the appropriate application, ensuring efficiency and longevity in their use.

What is the difference between ASTM A106 and ASTM A53?

ASTM A53 is Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless.

ASTM A106 is Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service.

Seamless Steel Pipe Common Standards

|

ASTM A53 Gr.B |

Black and hot-dipped zinc-coated steel pipes welded and seamless |

|

ASTM A106 Gr.B |

Seamless carbon steel for high temperature service |

|

ASTM SA179 |

Seamless cold-drawn low-carbon steel heat exchanger and condenser tubes |

|

ASTM SA192 |

Seamless carbon steel boiler tubes for high pressure |

|

ASTM SA210 |

Seamless Medium-carbon boiler and superheater tubes |

|

ASTM A213 |

Seamless alloy-steel boiler, superheater, and heat-exchanger tubes |

|

ASTM A333 Gr.6 |

seamless and welded carbon and alloy steel pipe intended for use at low temperatures |

|

ASTM A333 P9,P11,T22,T91 |

Seamless ferritic alloy-steel pipe for high-temperature service |

|

ASTM A336 |

Alloy steel forgings for pressure and high-temperature parts |

|

ASTM SA519 4140/4130 |

Seamless carbon for mechanical tubing |

|

DIN 17175 |

Seamless Tubes Made of Heat-Resistant Steels,typically used in the construction of boilers, piping systems, and other high-temperature equipment. |

|

DIN 2391 |

Cold drawn seamless precision pipe |

|

DIN1629 |

Seamless Circular Tubes of Non-Alloy Steel with Special Quality Requirements |

|

DIN 2391 |

specifies the technical delivery conditions for seamless precision steel tubes. |

|

EN 10305-1 and EN 10305-2 |

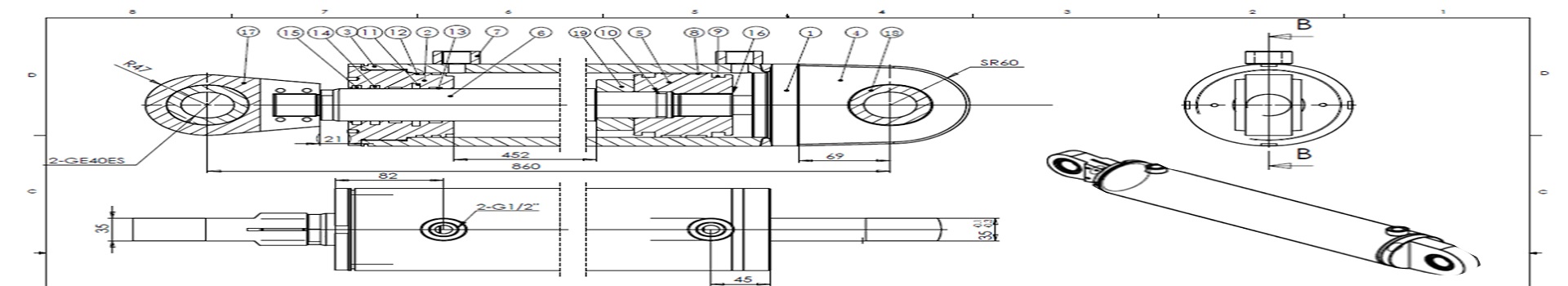

European standards that specify requirements for seamless and welded cold-drawn tubes,applicable to hydraulic and pneumatic power systems. |

|

ASTM A519 |

American standard that covers seamless carbon and alloy steel mechanical tubing. This standard is used for both hydraulic and pneumatic cylinders. |

|

JIS G3445 |

A Japanese standard for carbon steel tubes for machine structural purposes. This standard is frequently used for hydraulic cylinder applications in Asia. |

|

GB/T 8713 |

Chinese standard that specifies the technical conditions for hydraulic and pneumatic cylinder tubes. It is widely used in China and other regions for hydraulic applications. |

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry