Products >> Steel Pipes/Tubes/Chromed Bars >> Precision cold drawn pipe

Cold Drawn Precision Seamless Steel Tube

Cold Drawn Precision Seamless Steel Tube, Seamless Precision Steel Tube Manufacturers, Cold Drawn Pipe and Supply, Round Cold Drawn Seamless Hydraulic Steel Tube, Seamless Precision Steel Tube DIN 2391, Carbon steel precision tube, Seamless Carbon Steel Pipe Manufacturer

Specification for Cold Drawn Precision Seamless Steel Tube

OD: 48mm(1-1/2’’)~325mm(12’’)

WT: 3mm~45mm

LENGTH: 4m~10m

Standards & Grades for Cold Drawn Precision Seamless Steel Tube

EN: E215, E235, E355, C45E, 25CrMo4, 42CrMo4, CK45, S45C, E410, E470

DIN: ST52, ST52.3, ST52.4

GB: 20#, 45#, 16Mn, Q345B, Q345C, Q345D, Q345E, 25Mn, 27SiMn

Surface Treatment:

l Normal surface

l Inner surface or outside surface treatment, honing process, grinding, polishing, oiled...etc.

l Surface roughness Ra0.3um- Ra0.6um.

l End finish: Plain ends or bevelled ends.

H8 Tolerance:

|

ID range

|

Tolerance

|

ID range

|

Tolerance

|

|

18< d ≤30

|

+0/+0.033

|

180< d ≤250

|

+0/+0.072

|

|

30< d ≤50

|

+0/+0.039

|

250< d ≤300

|

+0/+0.081

|

|

50< d ≤80

|

+0/+0.046

|

300< d ≤315

|

+0/+0.081

|

|

80< d ≤120

|

+0/+0.054

|

315< d ≤400

|

+0/+0.089

|

|

120< d ≤180

|

+0/+0.063

|

400< d ≤500

|

+0/+0.097

|

Hot Treatment & Delivery Condition for Cold Drawn Precision Seamless Steel Tube

|

BK + C

|

BKW + LC

|

BKS + SR

|

GBK + A

|

NBK + N

|

Q + T

|

|

Cold Rolled

|

Cold Drawn

|

Stress Relieved

|

Annealed

|

Normalized

|

Quenched + Tempered

|

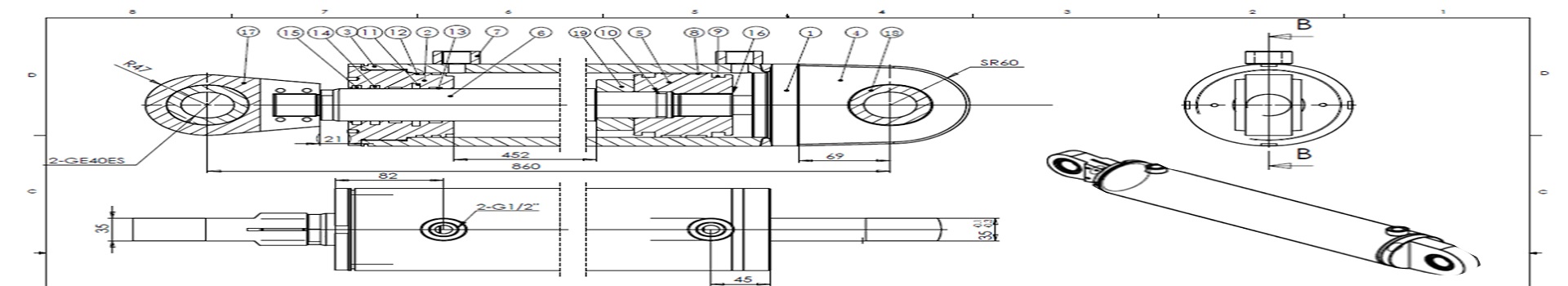

Application for Cold Drawn Precision Seamless Steel Tube:

Fluid Conveying

Hydraulic Cylinder

Pneumatic Cylinder

High Precision Machine Pipes

Agriculture Machine

Boiler Pipe & Industry Construction

Mechanical Processing

Pneumatic Cylinder

High Precision Machine Pipes

Agriculture Machine

Boiler Pipe & Industry Construction

Mechanical Processing

Automobile Industry

Condensing Unit Pipe

Cold Drawn Precision Seamless Steel Tube is a kind of high precision steel tube material processed by cold drawing or hot treatment. Its main features are no oxide layer on the inner and outer surface of the steel tube, no leakage under high pressure, high precision, high finish, no deformation during cold bending, no cracks in the flapping and flattening. Therefore, cold drawn precision seamless steel tube is mainly used in hydraulic system/pneumatic system, automobile manufacturing, project machinery, petrochemical industry, power station, boiler equipment and other industries.

DIN 2391-1 Chemical Composition

|

Grade

|

Chemical Composition(%):

|

||||

|

C max

|

Si max

|

Mn

|

P max

|

S max

|

|

|

DIN 2391 St 35

|

0.17

|

0.35

|

≥0.40

|

0.025

|

0.025

|

|

DIN 2391 St 45

|

0.21

|

0.35

|

≥0.40

|

0.025

|

0.025

|

|

DIN 2391 St 52

|

0.22

|

0.55

|

≤1.60

|

0.025

|

0.025

|

|

Grade

|

Chemical Composition(%):

|

||||||

|

Steel name

|

Steel number

|

C max

|

Si max

|

Mn

|

P max

|

S max

|

Al min

|

|

E215

|

1.0212

|

0.10

|

0.05

|

0.70

|

0.025

|

0.025

|

0.025

|

|

E235

|

1.0308

|

0.17

|

0.35

|

1.20

|

0.025

|

0.025

|

-

|

|

E355

|

1.0580

|

0.22

|

0.55

|

1.60

|

0.025

|

0.025

|

-

|

Previous Product:Automotive Parts Cold Drawn Seamless Steel Tube

Products Category

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry