AISI 1026 steel pipe:popular choice for hydraulic cylinders

AISI 1026 steel pipe is a popular choice for hydraulic cylinders and other applications requiring a combination of strength,

ductility, and machinability. This type of steel is a low-carbon steel known for its good balance of mechanical properties and ease of fabrication. Here's an overview of AISI 1026 steel pipe and its characteristics:

Chemical Composition

AISI 1026 steel typically has the following chemical composition:

Carbon (C): 0.22-0.28%

Manganese (Mn): 0.60-0.90%

Phosphorus (P): ≤ 0.040%

Sulfur (S): ≤ 0.050%

Mechanical Properties

AISI 1026 steel provides a good combination of strength and ductility.

Typical mechanical properties include:

Tensile Strength: 490-690 MPa (71,000-100,000 psi)

Yield Strength: 355 MPa (51,000 psi)

Elongation: 15-30% (in 50 mm)

Hardness: 156-217 HB (Brinell Hardness)

Key Features and Benefits

Strength: AISI 1026 offers sufficient strength for many hydraulic applications, ensuring the structural integrity of the cylinder under high pressure.

Ductility: This steel's ductility allows it to deform without breaking, which is essential for the dynamic loading conditions in hydraulic systems.

Machinability: Good machinability makes it easier to manufacture and finish components to precise tolerances.

Weldability: AISI 1026 can be welded using common welding methods, making it versatile for fabrication and assembly.

Cost-Effective: Compared to higher alloy steels, AISI 1026 is relatively inexpensive, providing a cost-effective solution for hydraulic cylinders.

Applications

AISI 1026 steel pipe is commonly used in:

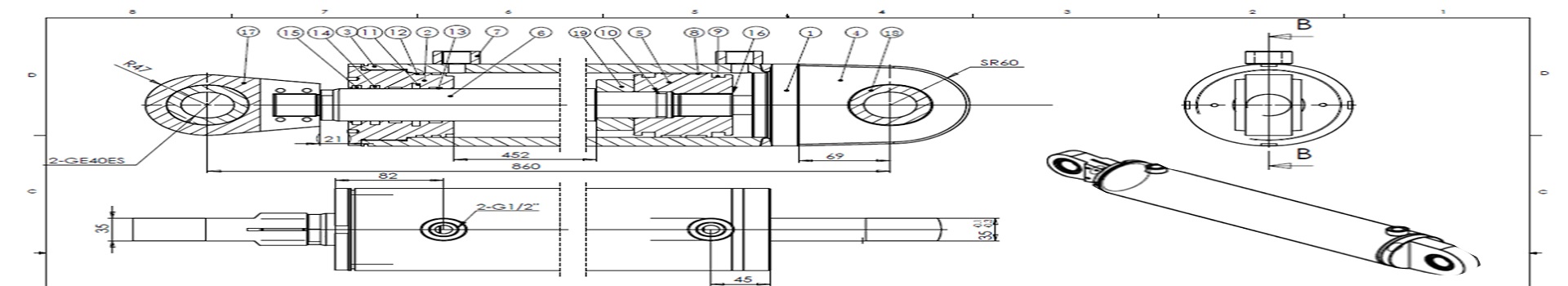

Hydraulic Cylinders: As the primary material for the cylinder tubing, providing a durable and reliable component for hydraulic systems.

Mechanical Parts: Such as shafts, gears, and machine parts requiring moderate strength and good machinability.

Automotive Components: Where moderate strength and good machinability are necessary.

Structural Tubing: In various construction and industrial applications.

Surface Treatment

For hydraulic applications, AISI 1026 steel pipes are often honed or skived and roller burnished to achieve a smooth internal surface.

This improves the sealing performance and reduces friction, enhancing the efficiency and lifespan of the hydraulic cylinder.

Standards and Specifications

AISI 1026 steel pipes conform to various industry standards, such as:

ASTM A519: Standard specification for seamless carbon and alloy steel mechanical tubing.

JIS G3445: Standard for carbon steel tubes for machine structural purposes.

By selecting AISI 1026 steel pipe for hydraulic lift cylinders, manufacturers can ensure a balance of performance, durability,

and cost-effectiveness, making it a suitable choice for a wide range of hydraulic applications.

ductility, and machinability. This type of steel is a low-carbon steel known for its good balance of mechanical properties and ease of fabrication. Here's an overview of AISI 1026 steel pipe and its characteristics:

Chemical Composition

AISI 1026 steel typically has the following chemical composition:

Carbon (C): 0.22-0.28%

Manganese (Mn): 0.60-0.90%

Phosphorus (P): ≤ 0.040%

Sulfur (S): ≤ 0.050%

Mechanical Properties

AISI 1026 steel provides a good combination of strength and ductility.

Typical mechanical properties include:

Tensile Strength: 490-690 MPa (71,000-100,000 psi)

Yield Strength: 355 MPa (51,000 psi)

Elongation: 15-30% (in 50 mm)

Hardness: 156-217 HB (Brinell Hardness)

Key Features and Benefits

Strength: AISI 1026 offers sufficient strength for many hydraulic applications, ensuring the structural integrity of the cylinder under high pressure.

Ductility: This steel's ductility allows it to deform without breaking, which is essential for the dynamic loading conditions in hydraulic systems.

Machinability: Good machinability makes it easier to manufacture and finish components to precise tolerances.

Weldability: AISI 1026 can be welded using common welding methods, making it versatile for fabrication and assembly.

Cost-Effective: Compared to higher alloy steels, AISI 1026 is relatively inexpensive, providing a cost-effective solution for hydraulic cylinders.

Applications

AISI 1026 steel pipe is commonly used in:

Hydraulic Cylinders: As the primary material for the cylinder tubing, providing a durable and reliable component for hydraulic systems.

Mechanical Parts: Such as shafts, gears, and machine parts requiring moderate strength and good machinability.

Automotive Components: Where moderate strength and good machinability are necessary.

Structural Tubing: In various construction and industrial applications.

Surface Treatment

For hydraulic applications, AISI 1026 steel pipes are often honed or skived and roller burnished to achieve a smooth internal surface.

This improves the sealing performance and reduces friction, enhancing the efficiency and lifespan of the hydraulic cylinder.

Standards and Specifications

AISI 1026 steel pipes conform to various industry standards, such as:

ASTM A519: Standard specification for seamless carbon and alloy steel mechanical tubing.

JIS G3445: Standard for carbon steel tubes for machine structural purposes.

By selecting AISI 1026 steel pipe for hydraulic lift cylinders, manufacturers can ensure a balance of performance, durability,

and cost-effectiveness, making it a suitable choice for a wide range of hydraulic applications.

Latest News

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry