What is Vertical Hydraulic Lift

A Vertical Hydraulic Lift

is a type of lifting equipment that uses hydraulic mechanisms to raise and lower loads vertically.

It is commonly used in various industries, including manufacturing, warehousing, and construction, for material handling, maintenance,

and transportation of goods and personnel. Here are some key features and components of a vertical hydraulic lift:

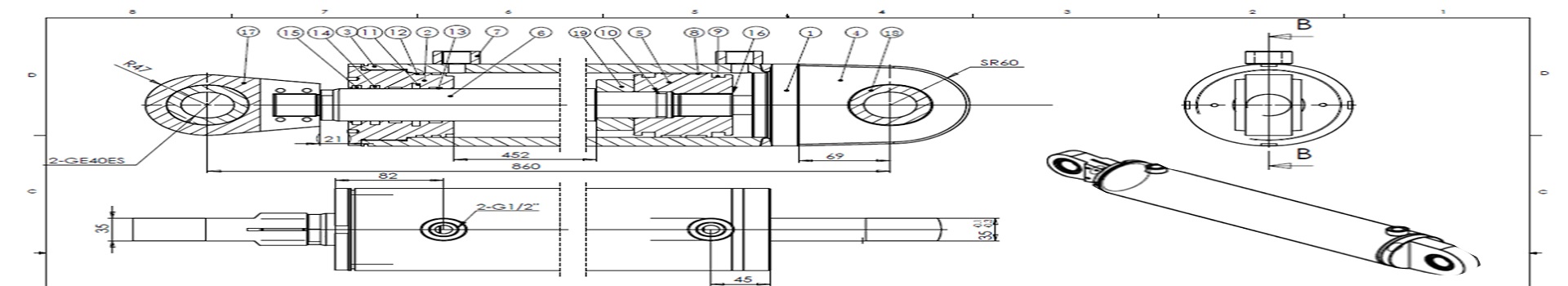

Hydraulic System: The core component, which includes a hydraulic pump, cylinders, and fluid. The pump moves hydraulic fluid into the cylinders,

creating pressure that lifts the platform.

Platform: The surface where the load or personnel are placed. The platform can vary in size and capacity depending on the specific application.

Guide Rails: These ensure the platform moves smoothly and vertically without swaying or tilting.

Control System: Allows operators to control the movement of the lift, including raising, lowering, and stopping the platform.

Safety Mechanisms: Includes emergency stop buttons, overload protection, and safety gates or barriers to prevent accidental falls or injuries.

Applications:

Material Handling: Used in warehouses and factories to move heavy materials to different levels.

Maintenance and Repair: Enables access to high or difficult-to-reach areas for maintenance work.

Personnel Lifts: Commonly used in construction and other industries to safely lift workers to elevated work areas.

Advantages:

Efficiency: Can lift heavy loads quickly and with minimal manual effort.

Safety: Equipped with multiple safety features to ensure safe operation.

Versatility: Can be used in a wide range of applications and environments.

Examples:

Freight elevators

Scissor lifts

Aerial work platforms

Dock lifts

In summary, a Vertical Hydraulic Lift is a versatile and essential tool for vertical transportation in many industrial and commercial settings,

leveraging hydraulic power to ensure efficient and safe lifting operations.

Latest News

Contact Us

Name: SAY HELLO WE LOVE IT!

Tel: +86-18763968079

E-mail: [email protected]

E-mail: [email protected]

WeChat: +8618763968079

Whatsapp: +8618763968079

WhatsApp

WhatsApp  Mail inquiry

Mail inquiry